Functional test

Key factors for greater productivity in mechanical test setups.

Our mechanical fixtures are extremely reliable and high capacity in that the latest requirements of the market are continuously integrated into their ongoing development. In addition, our customers regularly come to us with highly specific requirements which are then also incorporated into the technological features of our devices. The following concrete application will demonstrate this on the basis of the mechanical contacting of an enclosed assembly group from two sides.

The customer's requirements were as follows:

As there was no compressed air available at the test location the fixture had to function mechanically, with contacting from both sides. Both sides were to be accessed by activating a lever. The difficulty lay in the extremely high tolerance between the PCB and the housing, which made it necessary to position the plug contacts in a floating and self-centering way.

The display had to be visible and accessible for operation (touchpad). All the pins of the plugs were to be contacted in part with high current probes up to 10 A and via a special plug (similar to PS2).

And this application is our solution:

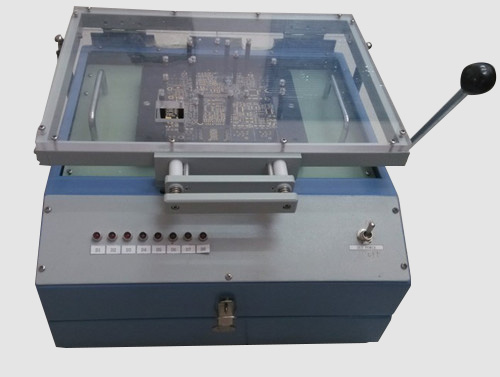

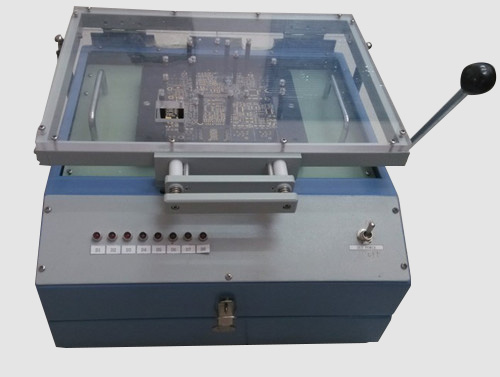

In the newly developed test concept the operator places the PCB on a carriage and then uses a lever to press it on to a fixed probe base with floating plug modules.

The second sideways lift is controlled by a crank which is driven by the primary carriage. This means that only a single manual movement is required to implement simultaneous contacting from both sides.

In developing the floating plug modules kokby was able to resort to well-established standards and use existing milling data from its comprehensive library of documentations. A new module only had to be created for the unusual special plug.

本为关键词:FCT Test Fixture